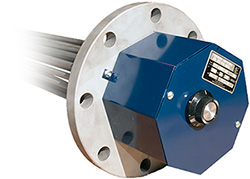

Flanged immersion heaters are constructed by brazing or welding elements into an ANSI or plate flange. These are intended for direct immersion into fluids and gases. The heater is to be installed via a flanged port in the tank or vessel. Flanged immersion heaters are available in a variety of flange sizes and materials. The heating elements are offered in a number of materials suited to a variety of fluid heating applications. Terminal housings are available for indoor, outdoor (weatherproof NEMA 4) and hazardous (NEMA 7) environments. Many options are available including thermostats, high limit and process thermocouples or RTD sensors. Since we are a made to order company, we can offer a large selection of sizes and configurations which are not listed below. Please contact us for assistance with your application.

Flanged immersion heaters are constructed by brazing or welding elements into an ANSI or plate flange. These are intended for direct immersion into fluids and gases. The heater is to be installed via a flanged port in the tank or vessel. Flanged immersion heaters are available in a variety of flange sizes and materials. The heating elements are offered in a number of materials suited to a variety of fluid heating applications. Terminal housings are available for indoor, outdoor (weatherproof NEMA 4) and hazardous (NEMA 7) environments. Many options are available including thermostats, high limit and process thermocouples or RTD sensors. Since we are a made to order company, we can offer a large selection of sizes and configurations which are not listed below. Please contact us for assistance with your application.

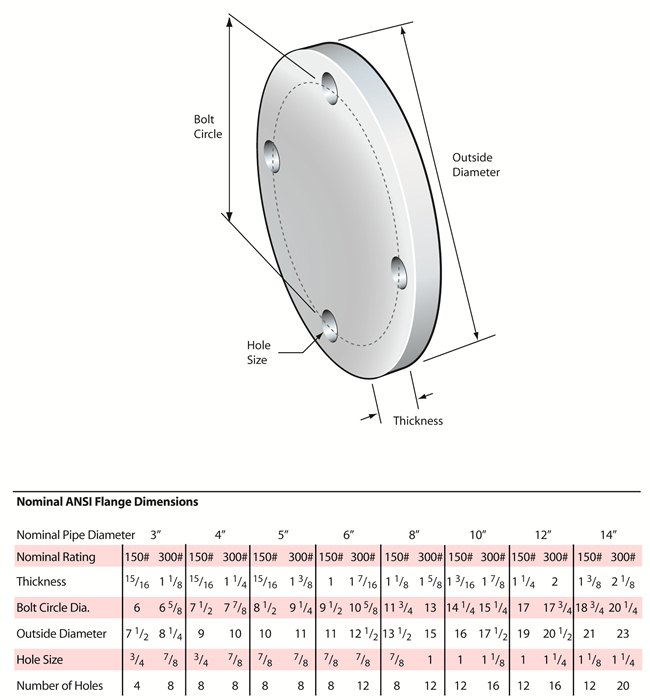

Standard Flange Sizes & Materials

| ANSI Flange Size

ANSI Flange Rating Materials |

2″ – 24″

150 lb, 300 lb, 600 lb Carbon Steel, Stainless Steel, Titanium |

Common Sheath Materials

| Copper

Steel Stainless Steel Incoloy 800 ® Inconel 600 ® Titanium |

Potable Water

Fuel Oils, Hydraulic Oils De-Ionized, R-O, Process Water, Mild Acids Water, Mild Alkaline Solutions, Air and Gases Water, Very Alkaline Solutions, High Temperature Air and Gases Sea Water, Very Alkaline Solutions, Some Acid Solutions |

Built in Thermostat Options

| Power Ratings | Up to 240 volts, 25-amp single pole, single throw (SPST)

Up to 240 volts, 25-amp double pole, single throw (DPST) Up to 600 volts, 15-amp triple pole, single throw (TPST) |

|

|

|

| Temperature Ratings | 0 – 100° F 50 – 250° F 160 – 540° F 320 – 700° F |

Built In Sensor Options

| Sensors | “K” thermocouple for high limit sheath protection and fluid sensing and temperature control.

“J” thermocouple for high limit sheath protection and fluid sensing and temperature control. 100 Ohm RTD Sensor for fluid sensing and temperature control. |

Terminal Housing Options

|

3”-150 # ANSI Flanged Heaters |

||

General Purpose Housings |

Moisture Resistant Housing |

Hazardous Location |

|

4”-150 # ANSI Flanged Heaters |

||

General Purpose Housings |

Moisture Resistant Housing |

Hazardous Location |

|

5”-150 # ANSI Flanged Heaters |

||

General Purpose Housings |

Moisture Resistant Housing |

Hazardous Location |

|

6”-150 # ANSI Flanged Heaters |

||

General Purpose Housings |

Moisture Resistant Housing |

Hazardous Location |

|

8”-150 # ANSI Flanged Heaters |

||

General Purpose Housings |

Moisture Resistant Housing |

Hazardous Location |

|

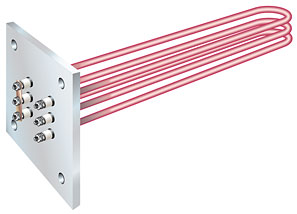

Non-Standard Flange Options / Designs |

||

Square Flange |

Round Flange |

Pipe Insertion |

Flange Heaters

| EXTRA FEATURES | DESCRIPTION |

| VOLTAGE | Flange heaters are custom-built and supplied with voltages up to 600V. |

| WATTAGE | Custom made heaters can be supplied with any requested wattage. |

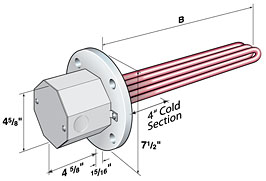

| LENGTH | Flange heaters are supplied with unlimited immersed lengths. When the immersed length exceeds 50”, it is recommended to install an internal vessel support. |

| EXTRA HEAVY WALL SHEATH | Heavy wall sheath (0.035” or 0.065” thickness) is provided in: • Incoloy® • Inconel® • Steel • Stainless steel |

| FLANGE SIZES AND RATINGS | Refer to the Welding flanges section on page 2.12 and 2.13 |

| PASSIVATION | Available Incoloy® and stainless steel sheathed heaters are supplied with chemically passivated sheaths. Note: Chemically passivated sheaths are highly corrosion resistant in most applications. Passivation process is carried out through electropolishing. Stainless steel flange heaters can come with passivated wetted surfaces (Teflon on top of the sheath). |

| WELDED ELEMENTS | Standard flange heaters are made of elements that are silver-brazed, ‘TIG’ or welded to the flange. Heaters are supplied with welded elements for the following sheath material: • Incoloy® • Stainless steel • Steel • Copper |

| BUILT-IN THERMOSTAT WELL | Built-in thermostat wells can be installed upon request. When ordering, please provide length and internal diameter. |

| BUILT-IN HIGH LIMITS AND THERMOSTATS | For process temperature control, built-in high limits and thermostats can be installed upon request. Standard built-in thermostats: Single pole device of a maximum of 600V up to 25 amps |

| BUILT-IN THERMOCOUPLES | Thermocouples can be mounted to provide sheath limit protection or temperature control. Configured temperature control and power controls are available to meet the requirements of any application. |

| VENTED or STAND OFF | Vented or Stand off housings prevent the connection wire from overheating in many high temperature applications. |

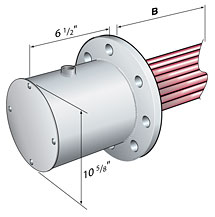

| SPECIAL TERMINAL HOUSINGS | Special terminal housings for all types of flange heaters can be made: • Moisture resistant • Explosion resistant When requesting an explosion-proof housing, please provide: • Class • Division or zone • Group • Temperature code for unsafe locations (Refer to Figures 1-4) |

| Flanged Heater Applications | SHEATH MATERIAL | FLANGE MATERIAL |

|---|---|---|

| Clean water, Freeze protection, hot water storage, Boiler and water heaters, cooling towers | Copper | Steel |

| Hot water, steam boilers, mildly corrosive solutions (in rinse tanks, spray washers) | Incoloy | Steel |

| Oils, Gases, Mildly corrosive liquids, stagnant or heavy oils, high temperature, low flow gas heating | Steel | Steel |

| Process water, soap and detergent solutions, Soluble cutting oils, demineralized or deionized water | Stainless Steel | Stainless Steel |

| Mildly corrosive solutions | Stainless Steel | Stainless Steel |

| Severe corrosive solutions, demineralized water | Incoloy | Stainless Steel |

| Light Oil, Medium Oil | Steel | Steel |

| Food Equipment | Incoloy | Stainless Steel |

| Features• | Benefits |

|---|---|

| • Standard flange heaters: ½" to 42 inch pipe |

• Easy to install |

| • 0.260”, 0.315”, 0.375”, 0.430” or 0.475”, 0.625” diameter |

• Easy to control |

| • 150lb, 300lb, 600lbs or 900lbs forged steel flange |

• Easy to maintain |

| • Steel, Incoloy®, inconel®, stainless steel, copper or titanium elements |

• Perfect for higher kilowatt output applications |

| • Available explosion and/or moisture resistant terminal enclosures upon request (NEMA 1, NEMA 4, NEMA 4x or NEMA 7. |

• Appropriate heater size provided for the application and fit |

| • Available custom sizes, wattages, and materials upon request. |

• Designed and built for safety |

| • Heating units are custom-designed to meet your specifications. | • CSA, CSA U.S. & UL approved |